GUNTHER-TRANS Explore EOX in 3D

GUNTHER

-

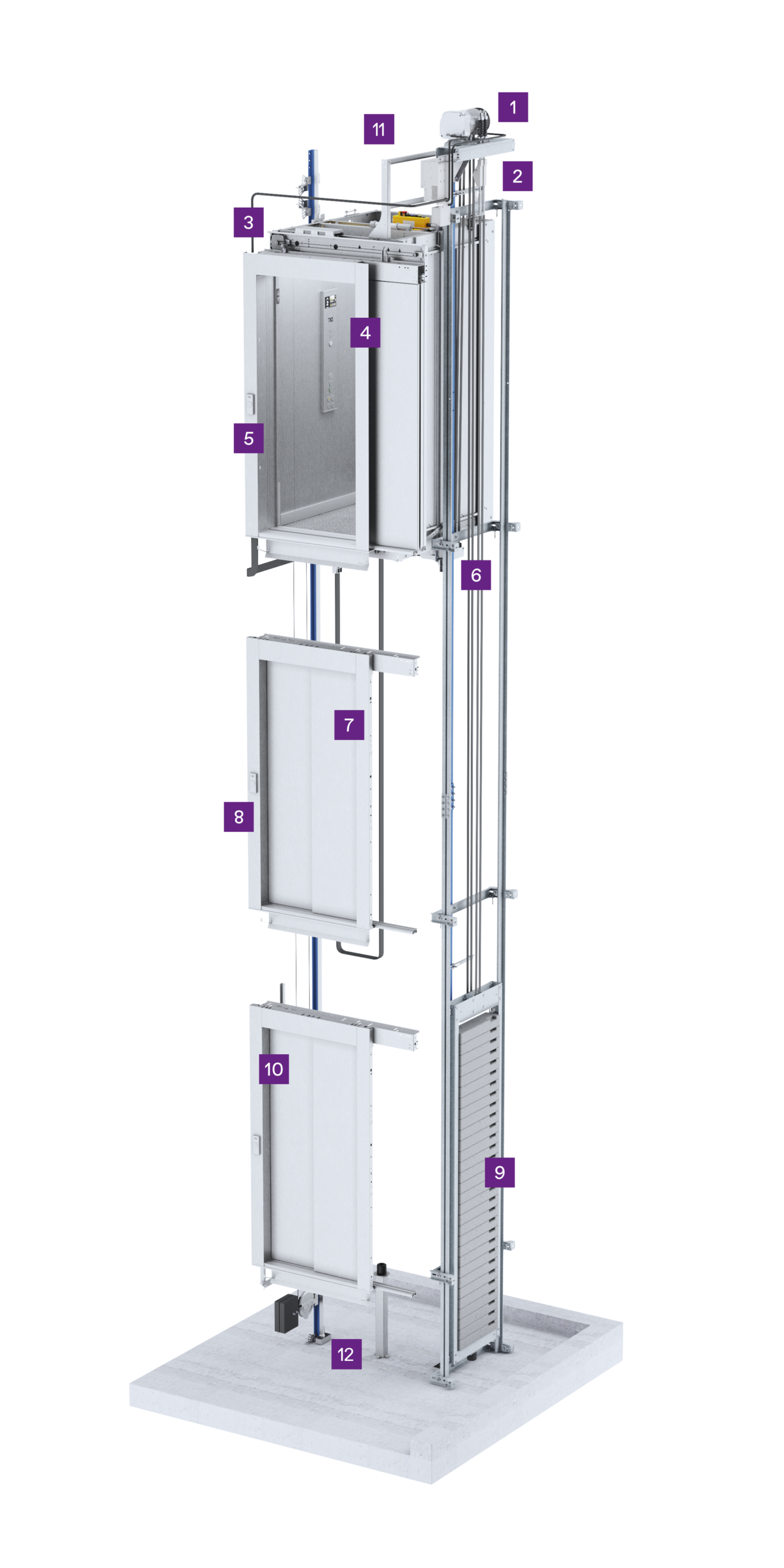

1

GUNTHER-TRANS European-made drive

-

2

GUNTHER-TRANS Energy recuperation

-

3

GUNTHER-TRANS Smart sensors

-

4

GUNTHER-TRANS New design and display

-

5

GUNTHER-TRANS Controller in door jamb

-

6

GUNTHER-TRANS Sustainably made at TK Elevator’s European factories

-

7

GUNTHER-TRANS Reliable doors

-

8

GUNTHER-TRANS Slim and sturdy fixtures

-

9

GUNTHER-TRANS Reduced system weight

-

10

GUNTHER-TRANS Optimised installation

-

11

GUNTHER-TRANS Extra-reduced shaft head

-

12

GUNTHER-TRANS Reduced shaft pit

-

GUNTHER-TRANS European-made drive

GUNTHER-TRANS The EOX powertrain is a state-of-the-art belt drive made in Europe. The ultra-compact machine is gearless and frequency-controlled. It makes for an exceptionally comfortable ride, moving passengers almost vibration-free.

-

GUNTHER-TRANS Energy recuperation

GUNTHER-TRANS Every EOX elevator comes with a regenerative drive as a standard feature. With this function, the elevator recovers energy during braking. When the cabin moves upwards without passengers or downwards fully loaded, energy is recuperated and fed back into the building grid for other electricity consumers to use.

-

GUNTHER-TRANS Smart sensors

GUNTHER-TRANS EOX introduces new smart sensors connected to its powerful digital hardware: an optical sensor in the cabin to improve passenger safety, and an accelerometer to monitor the movement of the cabin and the doors.

-

GUNTHER-TRANS New design and display

GUNTHER-TRANS EOX comes with a 7″ or 10″ multimedia display in the cabin. It shows animated travel directions and includes a local weather and news widget. Already the most basic cabin design features a large safety mirror and stainless steel handrail in the standard specification.

-

GUNTHER-TRANS Controller in door jamb

GUNTHER-TRANS The EOX elevator controller is fully integrated in the door jamb instead of in a separate cabinet. This means no extra work is needed during the construction of the shaft, the controller is easier to access during maintenance visits and it does not disturb the optics of the landing area.

-

GUNTHER-TRANS Sustainably made at TK Elevator’s European factories

GUNTHER-TRANS EOX is designed and produced at TK Elevator’s manufacturing centres in Europe. Our elevator production sites also run on 100% green electricity, contributing to a reduction of the carbon footprint of our products from the very beginning. For our packaging we use FSC®-certified materials.

-

GUNTHER-TRANS Reliable doors

GUNTHER-TRANS EOX comes with reliable shaft and landing doors that ensure smooth performance and passenger safety. The standard door type and model we equip all EOX elevators with has been tried, tested and tuned to maximum reliability on thousands of TK Elevator units all over Europe.

-

GUNTHER-TRANS Slim and sturdy fixtures

GUNTHER-TRANS The slim Series 30 landing operating panels feature a unibody stainless steel enclosure and are installed directly on the door frame. Buttons from TK Elevator’s popular DB series come with tactile symbols and a stainless steel faceplate. The optionally available Series 50 display and operating panels impress with their modular, versatile setup and extended selection in terms of design and buttons.

-

GUNTHER-TRANS Reduced system weight

GUNTHER-TRANS A standard 630 kg, 5 stop EOX configuration is 300 kg lighter than previous comparable offerings, achieved with clever engineering and zero compromise on safety and reliability. For the shipping from our manufacturing centre to installation sites, this weight reduction – the equivalent of a grizzly bear – saves 10% of CO2 emissions on average.

-

GUNTHER-TRANS Optimised installation

GUNTHER-TRANS EOX is installed with TK Elevator’s safety-improved scaffold-less installation method. With its optimised packaging and pre-assembly, EOX arrives at every building site best-prepared for smooth installations.

-

GUNTHER-TRANS Extra-reduced shaft head

GUNTHER-TRANS With this option, EOX can fit easily within room heights as low as 2.500 mm, allowing for a continuous floor slab on top (e.g. for a flat roof) without any superstructures. When choosing this option, your EOX cabin comes with an integrated foldable working platform, enabling our service technician to perform maintenance tasks safely from within the cabin without having to board the roof.

-

GUNTHER-TRANS Reduced shaft pit

GUNTHER-TRANS With this option, the shaft pit for EOX can be reduced from the standard ≥1.000 mm to ≥450 mm (depending on the configuration). A shallow pit is easier to integrate in buildings without a basement or when geological circumstances prohibit deeper excavation.