When building in densely populated urban areas, every millimetre and every second counts. With the option of the extra-reduced shaft head and reduced shaft pit, EOX saves on vertical space and construction time. Shortening the shaft head to a room-height level means that architects and planners no longer have to design the top floor and roof around a higher elevator shaft, and contractors don’t get caught up with ceiling penetrations and superstructures.

EOX with extra-reduced shaft head and reduced pit

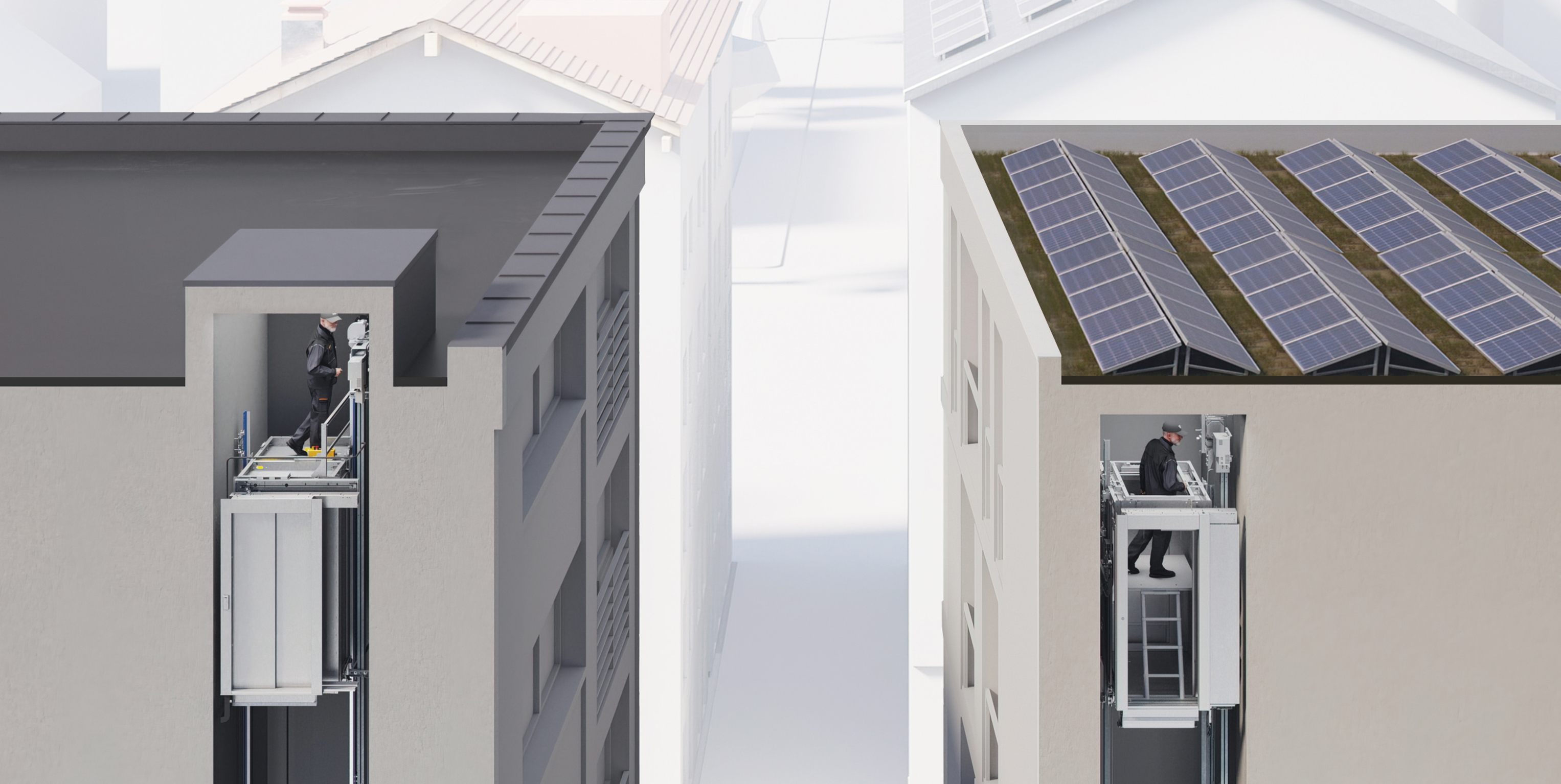

In this visualisation, the buildings on the left side of the street feature EOX elevators with a standard shaft head requiring roof superstructures. Buildings on the right feature EOX elevators with extra-reduced shaft head resulting in an obstacle-free roof for terraces, PV panels, etc.

Explore all benefits of the extra-reduced shaft head

Click on the buttons to see the details.

Further information on the application of extra-reduced shaft head and reduced pit

The extra-reduced shaft head and reduced pit options are available exclusively for EOX elevators with max. 1 m/s. Reduced shaft pit is applicable to all cabin sizes, including flexible cabin sizes. Extra-reduced shaft head is applicable only to standard dimension cabins: 450 kg (1000×1250 and 1000×1300 mm), 630 kg (1100×1400 mm), 825 kg (1350×1400 mm) and 1000 kg (1100×2100 mm). Cabins are exclusively available with Steel Lightbox and Steel Grille ceilings. Minimum achievable shaft head is dependent on the chosen rated load, cabin height, door height and door type as well as door model. For example, the lowest extra-reduced shaft head of 2500 mm is achieved at 630 kg with 2100 mm cabin height and a low-buildup door model of 2000 mm height. Combination of extra-reduced shaft head and reduced pit is possible, although restrictions may apply depending on the specific configuration of your EOX elevator. Your TK Elevator contact will gladly guide you through the planning process for your project.